Case Study

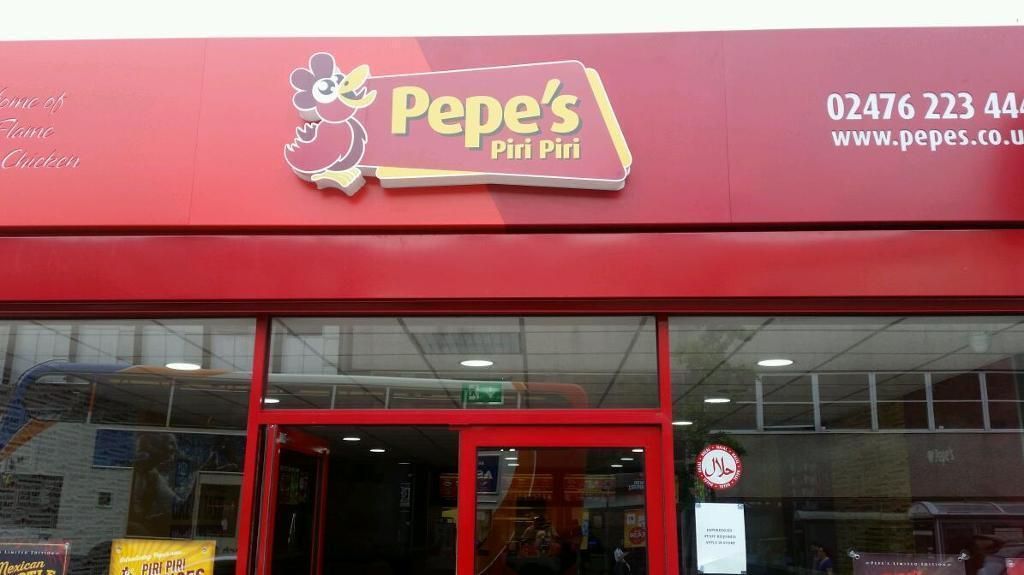

Property: Single-storey fast-food shop

Industry: Commercial

Contract Awarded to: RiskFire Ltd

Type of Contract: FRA

Location: 23 Trinity St, Coventry, CV11FJ

Project Duration: 1 day

Project Overview and Scope

RiskFire undertook a comprehensive Fire Risk Assessment (FRA) for Pepe’s Chicken with the objective of identifying fire safety deficiencies, ensuring regulatory compliance, and enhancing the safety of the premises for staff and customers. The assessment covered electrical safety, escape routes, fire doors and exits, combustible materials management, hazardous substances, staff competency, and the adequacy of existing emergency procedures and documentation. The scope also included reviewing the suitability of fire detection and emergency lighting systems, along with evaluating the need for specialist assessments under COSHH and DSEAR regulations.

Project Controls and Documentation Provided

- Electrical wiring inspection schedule

- PAT testing regime and compliance documentation

- Waste management and combustible storage guidelines

- Specification and recommendations for fire escape door replacement

- Interim evacuation procedures and external lighting/CCTV recommendations

- Written fire safety policy outlining responsibilities and maintenance duties

- Premises-specific emergency plan, including evacuation routes, PEEPs, and assembly arrangements

- Staff training records, fire warden/marshal training certificates, and induction materials

- Fire drill logs for staff and external contractors

- BS 5839-compliant fire alarm servicing schedule

- BS 5266-compliant emergency lighting test records

- Weekly alarm and smoke ventilation check logs

- Monthly emergency lighting inspection records

- Record-keeping system for all fire safety testing and training activities

Challenges and Solutions

The FRA identified a number of critical safety concerns requiring immediate and structured intervention. Electrical safety procedures were insufficient, with no formal testing of portable electrical equipment and no routine inspection of the wiring infrastructure. In addition, inappropriate use of extension leads was observed, increasing the risk of electrical ignition.

Combustible materials were stored inappropriately both inside and outside the premises, including waste bins positioned untidily near the building and combustible items kept close to ignition sources within the downstairs area. Hazardous COSHH items required more secure storage, and waste segregation practices were inadequate.

Escape routes presented capacity and compliance challenges, with only one fire exit available and the existing escape door falling short of safety standards. Fire doors had been wedged open, undermining compartmentation and increasing the risk of smoke and fire spread. The venue lacked a documented emergency plan, and staff had not received sufficient fire safety training or experienced regular fire drills. No written fire safety policy existed, and there were no records of fire alarm testing, emergency lighting tests, or ongoing maintenance activities.

RiskFire implemented a structured programme to address these deficiencies. A routine inspection schedule for the wiring structure was established and a PAT testing regime was introduced for all portable devices. Extension lead use was reviewed and corrected to eliminate daisy-chaining and unsafe adaptor use. Combustible materials were relocated to safe storage areas and a clear waste management system was introduced to ensure proper segregation and tidy external storage. All COSHH-related materials were moved to a locked, compliant storage cupboard.

To address exit limitations, RiskFire recommended replacement of the fire escape door with a compliant door that opens in the direction of travel and features a push-bar release mechanism. Interim evacuation procedures were implemented until these works could be completed. Recommendations were also made for improved external lighting and CCTV coverage to deter arson risks.

A detailed fire safety policy was drafted, clearly defining roles, responsibilities, and maintenance expectations. A premises-specific emergency plan was developed, covering warnings, evacuations, safe routes, assembly points, liaison arrangements with the fire and rescue service, PEEPs for disabled staff, and protocols for managing identified risks. Comprehensive staff training was conducted, including fire warden and marshal instruction, and all training sessions were documented. A structured programme of regular fire drills was introduced for staff and contractors. Maintenance schedules were established for fire detection and emergency lighting in accordance with BS 5839 and BS 5266. New record-keeping processes were implemented for all testing, inspections, drills, and training activities to ensure traceability and compliance.

Outcome and Outputs Achieved

The implemented measures resulted in significant improvements to Pepe’s Chicken’s fire safety management. Electrical fire risk was reduced through formalised testing regimes and improved equipment use. Waste handling and storage practices were strengthened, lowering combustible load both inside and outside the premises. Escape routes became safer and more compliant through planned door replacement and interim procedural controls. Staff competency improved considerably as a result of structured training, clear evacuation arrangements, and regular fire drills.

The premises now operate in line with BS 5839 and BS 5266 requirements for alarm and emergency lighting systems, and the introduction of a robust record-keeping system supports transparent compliance and ongoing safety monitoring. The newly developed emergency plan ensures that staff can respond effectively to fire scenarios, and secure COSHH storage reduces risks associated with hazardous substances. Overall, the FRA conducted by RiskFire has transformed Pepe’s Chicken into a safer and more resilient environment, with long-term procedures now in place to support continued compliance and operational safety.